I finally started in on the major truck project that was supposed to happen this spring before I broke my collarbone. I’m pulling the very tired 230 inline and 3-speed and swapping in a 18K mile 250 inline, and a 3-speed with overdrive. I’m also rebuilding the front suspension and adding disc brakes with a 2″ drop.

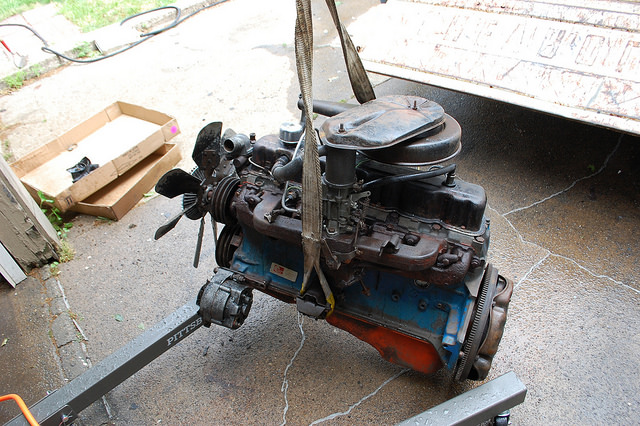

The day a friend came over and between her, my partner and I we had the hood, bumper and entire front clip pulled in an hour. That went so well we decided to pull the engine & trans while they were there. Disconnecting everything and getting the cherry picker set up took another hour. Then we spent the next 1.5 hours trying to get the driveshaft yoke to slide out of the transmission. It did not want to come out for anything. I ended up ratchet-strapping the engine to the front frame crossmember while it was supported by the cherry picker, then a combination of prying the yoke while someone violently rocked the engine from side to side and the third person trying to tighten the ratchet strap finally pulled it out.

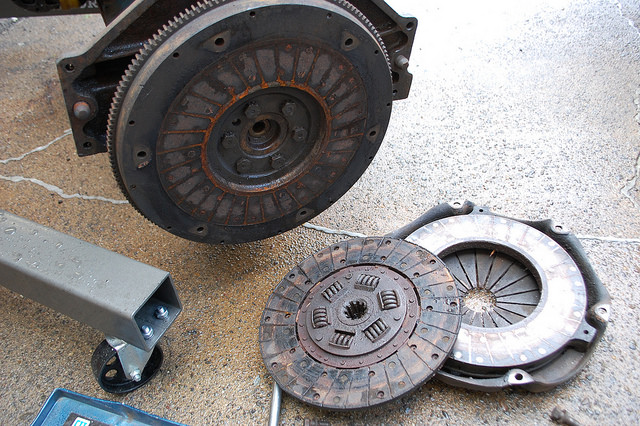

I separated the engine & transmission to free the bellhousing, the only major component I will be reusing for the “new” drivetrain.

I separated the engine & transmission to free the bellhousing, the only major component I will be reusing for the “new” drivetrain.

I also got the left suspension stripped off. The only part of the suspension & brakes I’ll be re-using are the upper & lower control arms(with new bushings), the center link, & steering box.

Once all the suspension & brake lines have been stripped off I will be doing major cleaning/degreasing in here, then either grinding or sandblasting the frame for painting before slapping new components on and running new brake lines. Then the new drivetrain can get assembled and installed.

This shouldn’t be a time-consuming project, but a combination of weather, timing and health are conspiring against me, so I’m just hoping I have it buttoned up enough to get the sheetmetal back on by snowfall.

I put some of my junk parts on the truck so I could use it. I have to admit it looks pretty cool like this. I drove it up the Boston to drop of some shelving that has been sitting in the truck since the fall, and I got more thumbs up and compliments with the truck like this than in any other trip.

I put some of my junk parts on the truck so I could use it. I have to admit it looks pretty cool like this. I drove it up the Boston to drop of some shelving that has been sitting in the truck since the fall, and I got more thumbs up and compliments with the truck like this than in any other trip.

So once the bumper was off, I stripped it of several layers of white paint, and ground down all the surface rust. I was pleasantly surprised to discover it doesn’t appear to be bent, and doesn’t have an dents in it.

So once the bumper was off, I stripped it of several layers of white paint, and ground down all the surface rust. I was pleasantly surprised to discover it doesn’t appear to be bent, and doesn’t have an dents in it. Before I could start the repainting, I had to address the gouge I’d made with the cutting wheel when I cut the various bolts off.

Before I could start the repainting, I had to address the gouge I’d made with the cutting wheel when I cut the various bolts off.

Once that was done the bumper was coated in MasterSeries & primer like all the other parts.

Once that was done the bumper was coated in MasterSeries & primer like all the other parts.

The first order of business was to unbolt everything from them and get to work grinding all the paint off. The grille panel has this odd spot of rust. Which, given its location, was probably the result of battery acid from a battery leaking or exploding, fortunately it was only surface deep and came right off.

The first order of business was to unbolt everything from them and get to work grinding all the paint off. The grille panel has this odd spot of rust. Which, given its location, was probably the result of battery acid from a battery leaking or exploding, fortunately it was only surface deep and came right off.

Fortunately this turned out to be an easy fix, the brace on the back had a cutout where the GMC grille hole was supposed to be, so I just had to drill them out and I had the

Fortunately this turned out to be an easy fix, the brace on the back had a cutout where the GMC grille hole was supposed to be, so I just had to drill them out and I had the  I painted the backs of both with Rustoleum, then sprayed the back of the grille panel with truck bed liner. I think it was because I didn’t dust the parts with primer when the MasterSeries was still wet, but when the bedliner went on it crinkled and lifted most of the Rustoleum off the back of the grille panel.

I painted the backs of both with Rustoleum, then sprayed the back of the grille panel with truck bed liner. I think it was because I didn’t dust the parts with primer when the MasterSeries was still wet, but when the bedliner went on it crinkled and lifted most of the Rustoleum off the back of the grille panel.